Effects of various elements in aluminum alloy castings

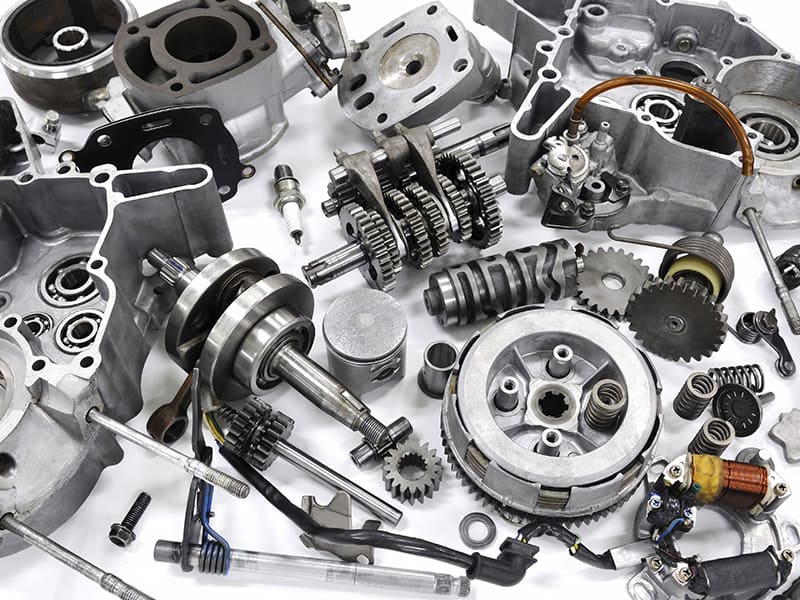

Today we released the influence on alloy elements, and then we will take out the others on aluminum alloy. If your customers are uncertain about the choice of materials, we can provide professional material recommendations.