Research on High Strength Die Casting Aluminum Alloy and Its Heat Treatment

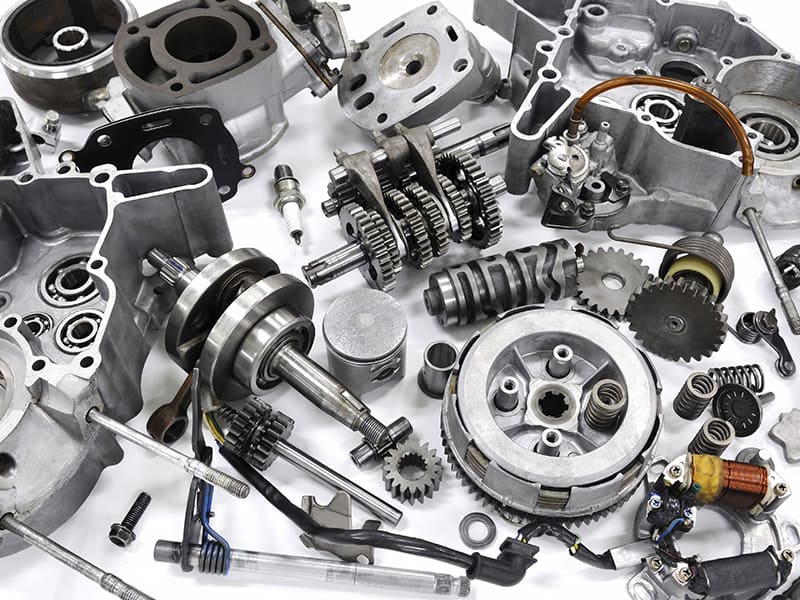

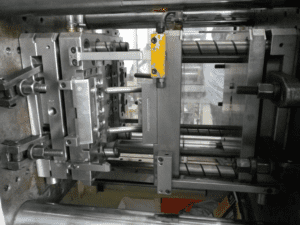

Compared with ordinary aluminum alloys, high-strength die-casting aluminum alloys have better strength and corrosion resistance and use in machinery, automobiles, aerospace, and other fields. The demand is mutual…